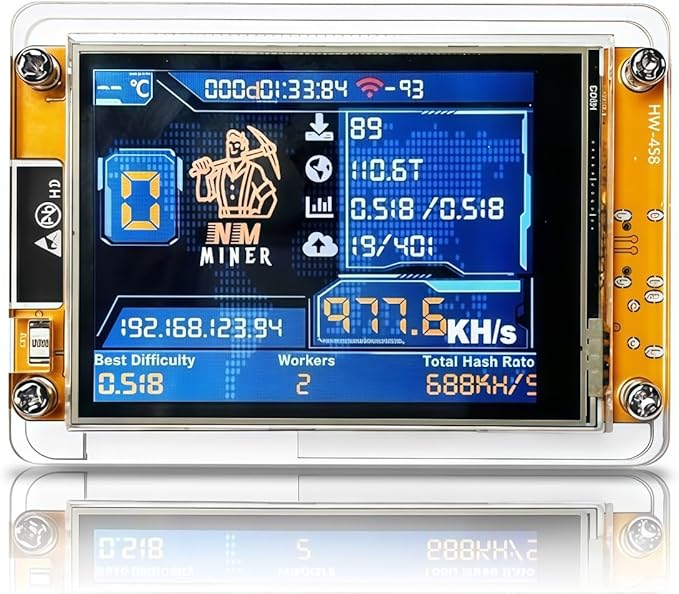

Saw people using these, figured I’d try one.

Took over a month to arrive, had it put together and working fairly quickly. But it didn’t last. After about a week, I arrived in my office to see it at 80%. Assume it started an update. Let it sit there for a few hours, didn’t move. Rebooted, Bricked.

Tried for hours to look for bin files or software to reflash. None worked. So chalk this up to lesson learned. Will try to turn it into a media player or hacking tool. Will keep you updated.

UPDATE: During a quiet weekend, I was able to sit down and learn more about these bit miners. Unknown to me when I attempt to reflashed the device, I erased my license. A new license costs $3, so it wasn’t a big deal, however it would have been easy to recover license before flashing had a known. SO BEWARE!

Also depending on which unit you purchase, these can be daisy chained, which would be nice if you had more than one (thinking about getting another to up my odds LOL).

The stand/case it comes with isn’t the best, it falls over easily. So I am printing stands now. LOVE the 3d Printers!

OH and 80% means it wasn’t reaching the BitCoin Pool server, seems they changed/rearranged them. Once I learned that it was an easy fix, one that could have be avoided.