Weather this year in Middle Tennessee has been nice, chilly but nice. Not a lot going on outdoors. So I’ve been 3d printing up a storm. Designing products for work, such as badge holder, mini-me’s for team, signs for our new offices, new desktop organizer, and the list goes on. Both Bambu printers have gone many days with non-stop printing with only very minor issues, generally at no fault of the printers. I see no stopping with these two for the remainder of Winter.

Category: 3D Printing

Bambu Lab 3d Printers

An Update:

As you might be aware, we run two Bambu Lab 3d Printers. A P1S (we call it the cheap one), and an H2D with two AMS units (the big one). Thru no fault of Bambu Labs we broke both of them. Mostly through trying to “fix”. Having not watched any YouTube videos before hand, we just ended up making matters worse. HOWEVER, we have been able to fix both printers, here is what happened.

The Big printer, had what we found out was a minor issue, filament broken it feed tube. We took it to mean there was a problem with feeding into the print head. So in trying to remove the feed tube, be broke the “Dual Extruder Idlers and Filament Sensor”. Basically the part that holds the feed tubes and directs filament into print head. And the Cheap one, wasn’t laying any plastic on plate, meaning it wasn’t printing. We tried using an “unclogged”, and ended up making the hole into the hothead bigger than it was supposed to be.

But ordering parts from Bambu labs was simple and not that expensive, waiting for them to arrive is the hard part. It takes at least a weekend and a half to get here. But we ended up stocking up on spare parts, mostly stuff prone to breaking (we assume).. And we have learned a lot about the care and maintenance of the printers.

So unlike the 3d printers we had in the past (see out on this site), we printed days with little or no issues, they break mostly through no fault of the printers themselves, they are very forgiving and doen’t cost an arm and a leg to fix.

Again, highly recommend any of the Bambu Lab printers.

Bambu Lab P1S

Have been having so much luck with he Bambu Lab H2D 3d printer, I wanted to try printing some TPU items. (TPU (Thermoplastic Polyurethane) filament is a versatile 3D printing material that is a blend of plastic and rubber, resulting in a durable, flexible, and high impact-resistant print. ) Problem is the AMS 2 doesn’t support TPU, it EATS it. Causing user to disassemble AMS to clear out the misfeed. So during their Black Friday sale (45% off) we purchased an older P1S JUST FOR TPU printing. This printer shows its age in the Bambu line of products. Smaller B/W display, smaller build area, one print head and speed. However it works. Slightly more difficult to setup than the H2D, but not painful at all. In less than 30 minutes of unboxing, we were printing flexible items. It does tend to string a bit more, and braces are a little harder to get off. But all and all, another great product.

Back to 3D Printing with Bambu H2D

After a few years frustration with my old Robo printer, I thought it was time to upgrade and talk about an upgrade. The New Bambu Lab H2D is amazing! Can’t say it is idiot proof, cuz you need a little 3D print knowledge to get everything working. But once it works. WOW! I’ve printed more in the first two weeks of owning this printer than I could with my last three, without major issues! No clog cleaning, no miss-fed filament and only a small amount of spaghetti.

Purchased the AMS 2 as well, for multi-color printer was worried after seeing reviews of the first AMS. But it makes multi color printing almost effortless.

Oh, yeah, it is fast, after bed leveling and warm up, it flies.

The software so far has been pretty good, getting used to filament selection, learning that the external roll is required and counts as ‘1’.. But after that, I am printing like a mad man. The one thing I’ve noticed about the software it give and estimate cost of printing. One of those things I always wondered about.

Expect great thing from Bambu Labs. Lets hope they keep the current trend going.

Oh I am going to look into upgrading to the 40 watt laser add-on. So far it isn’t showing up as an add-on option. Only for purchase. It would need to replace the glass sides and attached to current print head, but I could see. it happening..

UPDATE: This printer is amazing. This is the first printer I’ve been able to run for DAYS without a single issue. So, impressed with it I ordered a second AMS 2 system, so now I can select from 8 spools of filament. The software is easy to figure out and use. — The Build area is MASSIVE.

Added Second AMS – More Color, More Options at a price.

Getting stuff indoors done.

Winter makes staying indoors, the more enjoyable choice. Been using the time to catch up on projects and cleaning our “problem” projects. Notably, two. The Robo 3d R1 printer and the laser engraver.

The 3D printer hasn’t wanted to print, no matter what I’ve tried. Pretty sure I had a post a while back on the subject. Starting testing it again, before it went to dump, reading posts for people having similar issue. Turns out it was my “new” filament that had gotten “damp” and needed to be dried. Crazy. So I bought new filament, the first in years. It came vacuum sealed.. And the Robo worked on the first try, I was amazed. Then started researching “damp filament”, found out you can get little heaters that dry out the filament. Again, amazing.

Purchased a little filament drier found on eBay for less than $50. Let it run for a few hours (12 hours to be exact), and FANTASTIC. Filament I haven’t been able to print with EVER, worked perfectly fine. So notch one up for the Internet. One Fix, Fixed.

The other project was moving my xTool M1, into my office and creating a venting system so my office and my house doesn’t fill with smoke. Even added power switches for both the blower and the Air Assist system. Did a few tests print and it works great.

Weekend well spent!

UPDATE: Ending up giving the Robo 3d printer away. Upgraded to the Bambu Lab H2D printer with AMS Pro 2. Fantasic printer. Almost non-stop printer since I got it, months again. Still no issues.

xTool M1 Laser

Having used laser engravers, or laser tools in the past, I wanted to get back into it. Having blown my laser tube in my old Chinese laser engraver (40 watt), and finding it cost almost as much as a new laser cutter for a new tube I held off buying a replacement. Found the M1 on ebay as a refurb, for almost half off, I jumped at it. Then spent $$ for the add-ons. Even with 10 watts, and easy to use software, it if very useful.

The Chinese engraver, required a thumb drive with their software to operate, and it was poorly translated to english. At least parts of it, a great deal of the software was still only in Chinese. It was usable, with a fight. Plus it required cool water to keep the tube cool. My mistake was forgetting about checking the water before use, after a nights freeze. So ice in tube, not good.

The xTool Creative Software, has its limits, not as much control as I was used to, but more than enough to get the job done. I am hoping they add features. OH and the software is Free, no thumb drive key.

The built in camera is a huge plus, I mean HUGE. Makes alignment and reusing scrapes much easier.

Looking into upgrading it to a higher power laser, which would cut down on the number of times I have to cut over the same time. Translation, faster printing.

Haven’t use the rotary, or the air assist. But I’ll get there.

Right now I am making project boxes for Raspberry Pi Pico projects, very handy tool for that.

UPDATE: One difference I’ve noticed between 3d printing and laser engraving. 3d printing produces less waste. Yes there is poop, with 3d printing. But with laser cutting, you end if with piles of scrap sheets of wood. Both have their places can’t wait till mixed media printing becomes a thing.

So far mixed media printing in 3d allows you to add fabric layers, magnets or nuts while printing. Would love to see mixed wood cuttings with plastic inserts, etc..

3D Printing, at last.

For years I’ve been trying to find a 3d printer that works reliably and has good support. Started off with a Makerbot kit, which worked well, for awhile. Then Makerbot went crazy with the pricing and went private, so I lost heart in the company.

From there we switched to Solidoodle 3,  Supported Solidoodle Press though a kickstarter, took almost two years to receive and NEVER got a good print out of the unit. The unit looked great though. Back and forth with tech support to the point that they wanted me to send back unit for repair. Which I never did, thank goodness. They were out of business weeks later.

Supported Solidoodle Press though a kickstarter, took almost two years to receive and NEVER got a good print out of the unit. The unit looked great though. Back and forth with tech support to the point that they wanted me to send back unit for repair. Which I never did, thank goodness. They were out of business weeks later.

A few weeks ago I received notice from Robo, that they were discounting remaining R1+ units, I jumped at it. So far the unit has printed everything I’ve requested, even prints that took 8 hours. A total first.

The units LEDs stopped working, so I contacted Robo, after a few trouble shooting emails, I have new Lights and a have received answers to all my issues quickly and without a lot of template replies. Fantastic printer at low cost.

Solidoodle – Rest in Peace

Seems Solidoodle, the 3d printer company, has ceased operation (as of March of this year).

Can’t say I am very surprised, we have two different Solidoodle printers. Neither has worked well, and tech support was a joke. The last resolution was to send the printer back for trouble shooting, had it boxed up ready to go, but thought better of it. Glad I didn’t send it back now. Although it still has an issue, at least I still have the printer.

Sad an American company couldn’t make a go of it and the Press is a pretty printer.

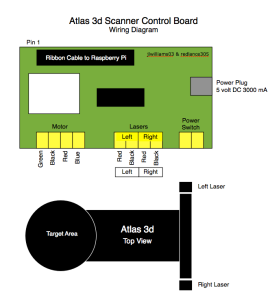

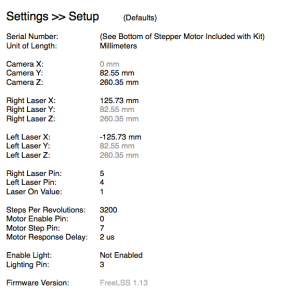

Atlas 3D Scanner – Kickstarter and Kit

Looking though Kickstarter I found a guy building a 3d scanner, that was printable, and had an option that included all the hardware (motors, laser, etc). You just had to print the parts and assemble.

And of course, you have noticed I haven’t had any luck with my Solidoodle 3d printer, so the kit has just been sitting. UNTIL they started selling laser cut kits. Bought one on the spot.

My stepson and built it over a long weekend, but couldn’t get it to align. So I did some surfing and never got a correct answer, until I found SoliForum. Found some real helpful people and I was able to piece together the problems.

Solidoodle 3D Printers

I had high hopes for printing in 3D, maybe too high.

A few years back I purchased a MakerBot Kit, from MakerBot. Which took almost a week to build, align and get working. But it did a fair job at printing 3d objects. But we wanted better.

So I order a Solidoodle 2nd Generation printing. Much sturdier I thought, will work much better. First day the extruder broke, mostly due to a different method of loading filament than the MakerBot. My fault. I purchase parts to repair the head, and even a replacement head. IT NEVER printed a 3D model as good as the MakerBot, which is sad.

Then last year Solidoodle introduced the Press, a self leveling, unibody 3D printer. Ordered, and waiting 5 months. At first look the printer is impressive. large 8x8x8 print area, filament holder inside the case. I was excited.

Went through the calibration test run, hopes quickly died.

Filament doesn’t adhere to the print surface at all, but it holds on to the extruder very well.. Prints one big blob of plastic.

On top of that the print bed rises to meet the extruder, when printing completed or it stopped, I fully expected the bed to lower. The print bed didn’t lower. So for big handed users like myself getting in the printer to clean the blob is difficult.

So, in no way can I recommend this printer. I’ll detract this if Solidoodle support gets back to me with fixes.

[UPDATE #1]

After getting the standard, set temp higher for both extruder and build plate, and spraying the build plate with hair spray. I finally got what has to be my best print ever.

HOWEVER!!

When I attempted to print a second box today, in greater detail, the extruder was clogged. I attempted to increase the temperature to the extruder, extruding 100mm of filament and retracting the filament. However all I got was a thumping noise out of extruder head. Emailed tech support, AGAIN. And of course they are closed on weekends.

~David